Welcome to NDSU Libraries Digital Fabrication Lab!

Today's Hours:

| Digital Fabrication Lab | 1pm – 5pm |

|---|

Hours subject to change in observance of university holidays and semester breaks. See exception details.

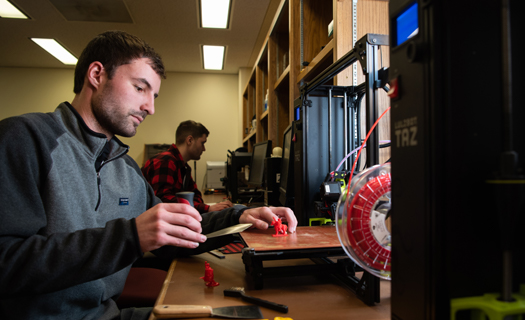

The Digital Fabrication Lab is a student-centered and easily accessible workspace. The Lab provides access to tools, training, and the support needed to design and produce prototypes and projects for personal, academic and professional purposes.

Regardless of experience level or major, the Lab offers opportunities for hands-on use of current and emerging technologies to solve problems, design creative works, and develop prototypes for entrepreneurial endeavors.

Vision for the Digital Fabrication Lab Redesign and Expansion, featuring the CoLab: A Space for Students, Designed by Students

Zachary Drechsel, Interlibrary Loan Associate

Phone: 701-231-9746

Location: Main Library 121

Email: zachary.j.drechsel@ndsu.edu

- Equipment

-

Universal Laser Systems 6.75 75watt Laser Engraver

- Bed Size: 18in x 32in

- Most Common materials: Cardboard, Cardstock, Assorted Woods, Plywood, Plexiglas (acrylic)

- (*Requires Safety Training and Laser Training/Certification)

Elegoo Saturn S Resin Printer

- 196 x 122 x 210

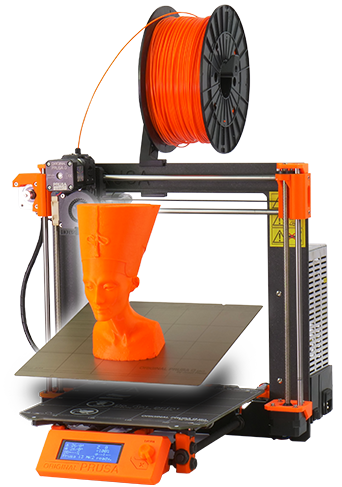

Prusa i3 MK2 & MK3

- Print Bed Size (mm)

- 250 x 210 x 200

- Uses PLA PETG

- Software: PrusaSlicer (free)

Nomad 883 Mini-Mill

- Bed Size (mm)

- 203 x 203 x 76

- Soft materials: Foams, Plastics, Composites, Wood

- Software: Meshcam (paid)

Sense 3D

- Operating Range (m) : Min: 0.2. Max: 1.6

- Field of View: Horizontal 45° Vertical: 57.5° Diagonal 69°

- Scan Volume(m): Min: .2 x .2 x .2. Max 2 x 2 x 2

- Depth of image size (pixels): 640 x 480

- Software: 3Dsense

- Exports: STL , OBJ

Matter and Form 3D Scanner

- Scan Accuracy(mm): +/- .1

- Maximum Object Size (mm): Height 248 Diameter: 177

- weight (kg) 2.7

- Software: MFStudio

- Exports: STL, OBJ, PLY

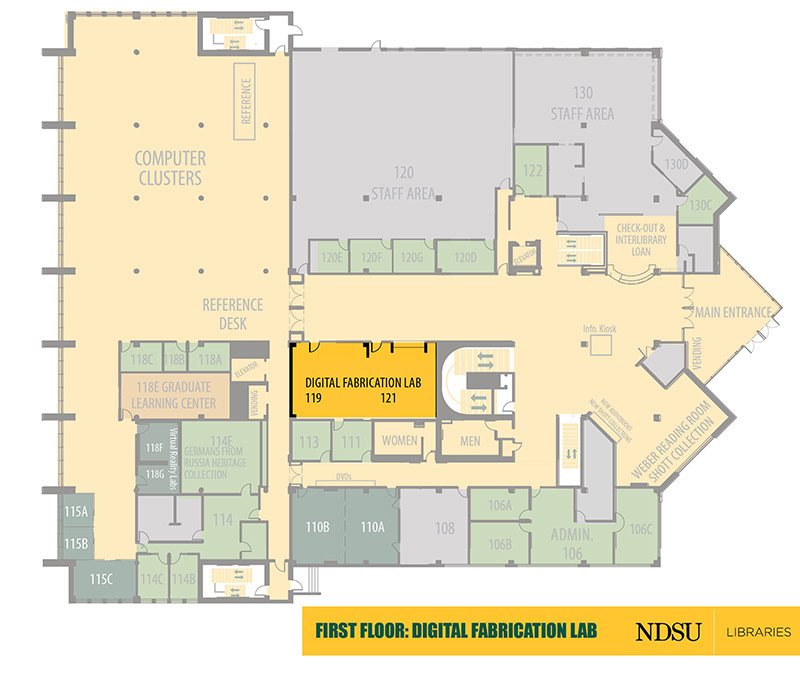

- Floor Map

-

Located on the first floor of the Main Library.

- FAQ

-

What Type of File do I need?

The prefered files in order: .STL .OBJ .STEP

these three file types are the most common and are a universal format.

The preference is for a .STL file. STL is an abbreviation of “stereolithography”. This is a file format native to the stereolithography CAD software created by 3D Systems. It is a universal and recognized by most 3D software.

What type of Software Should I use?

This is a two tiered question.

Firstly, to design a project, you need a CAD program. In the lab we use Autodesk’s Fusion 360. This is free with an Education ID and seems to be the easiest for students to learn. It features the ability to interface with 3D printing programs and has a CAM (computer aided manufacturing) feature for the desktop CNC Mills.

Students may also use CREO or SolidWorks but we do not currently have these software licenses or software loaded onto our machines. These are two popular professional grade 3D modeling software programs. Google Sketchup is also an alternative, but students can run into problems exporting an .STL depending on the version they have access to.

The second tier of software is something called a slicer. This is a program that writes the “G Code”. G-code is a language in which users tell computerized machine tools how to make something. The G Code contains information like temperature of extruder head, speed at which the head travels, and coordinates of where to place the cutting head or extruded plastic.

The Slicers that the Lab uses are as follows: Slic3r, PrusaSlicer and Cura. We instruct students which one to use based off of what printer they desire to use.

Ultimaker = Cura

Prusa 3D Printer = Slic3r or PrusaSlicer

What type of Filament do you have?

We supply patrons with the filament used. The Filament brand we use varies from semester to semester.

We offer PLA (polylactic acid) filament. We use the Slicer to determine the weight of the part and support material if needed. We do not charge for the filament used in failed prints.

We do not allow outside filaments to be used in our machines. Quality of PLA differs from manufacturer to manufacturer. We use our own trusted materials to eliminate the variables of misprints and to ensure we do not damage our machines with sub-par filament. Proceeds from the payments go towards the Digital Fabrication Lab and to improve or refresh the equipment.

- Policies

-

*Reproduction, duplication, or matters of infringement of existing Copyright, Patents, or Trademarks is not permitted. This includes the NDSU Logo and the NDSU Bison Athletic's logo and the likes of others.

Safety

Like all campus labs, we follow safety protocols. We want to be sure that you and our other guests work in a safe environment. All NDSU campus wide policies are enforced in the lab as well as few that are unique to the space. Creating a culture of safety in our digital fabriaction lab is every community member's responsibility.

Eligible Users: All Faculty, Staff, and currently enrolled students may use the Digital Fabrication Lab.

- Eye Protection must be worn when necessary. If another member is using a tool requiring eye protection, you will be asked to do so as well.

- No food or drink is allowed in the Digital Fabrication Lab.

- Wear appropriate footwear, no open toe shoes.

- Hair, jewelry, and loose fitting clothing need to be secured prior to entering area

- Outside chemicals and materials need to be cleared with the Emerging Technologies Coordinator before use.

- Impairment: Do not work in the shop when sleep deprived, on medication that influences your judgement or dexterity, or while under the influence of drugs or alcohol.

- Use the right tool for the right job. Do not modify tools or use them in unintended ways. Doing so may result in being asked to leave or losing access.

- Clean up work areas after you are done.

- Never Dispose of Chemicals in the standard trash or by dumping them into sink or floor drains.

- We do not currently allow for storage of personal material, equipment, or projects.

The list provided is a general overview of safety requirements. You may be asked to follow rules not listed dependent on project or task. We ask that if you are unsure of how to use a machine, tool, or complete a task, please ask the supervisor on duty. We are here to help and we may have a better solution or campus resource. Understand you may be told a project or procedure may be deemed unsafe for the space or for other occupants, and turned away.

We reserve the right to deny access or use of resources.

Usage Policy

The NDSU Libraries' equipment may be used only for lawful purposes. No one will be permitted to use the Libraries' 3D printers to create material that is:

- in violation of NDSU policies.

- prohibited by local, state or federal law.

- unsafe, harmful, dangerous or poses an immediate threat to the well-being of others. (Such use may violate the terms of use of the manufacturer.)

- in violation of another’s intellectual property rights. For example, the printer will not be used to reproduce material subject to copyright, patent, or trademark protection.

See NDSU's copyright policy for more information.

We reserve the right to deny any work/project to be completed in facility.